Shipyard

Conley Marine Services’ shipyard offers our clients a full service facility to include a 700 ton drydock, shipfitting/welding for steel repairs, tailshaft and rudder repairs/fabrication, pipe repairs, a full service machine shop, HVAC repairs, electrical repairs, blasting/painting, major and minor vessel modifications, barge repairs, engine removal and installation and engine alignments.

Machine Shop

We offer a full service machine shop to include shaft refurbishment and fabrication up to 12 inches, rudder refurbishment and fabrication, bearing, strut and stern tubes, engine swings, engine and gearbox alignments, etc.

Maintenance Planning

Downtime is costly. Unscheduled downtime is exponentially more costly. Many successful organizations have embraced the concept of “Planned Maintenance” in one form or another.

About us

Conley Marine Services

Where our customers’ safety and vessel availability matter.

Conley Marine Services was formed in 2016 as a wholly owned subsidiary of Conley & Associates, Inc. for the purpose of providing regulatory compliance services to the tug and barge industry. We have helped many companies achieve not only Subchapter M compliance, but also compliance with other Subchapters including I, L and T.

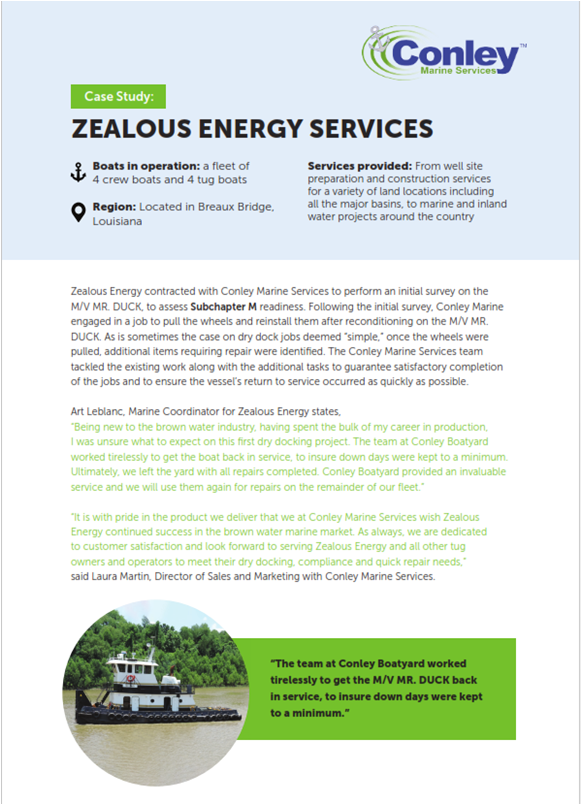

In September of 2018, Conley Marine Services acquired the shipyard located approximately 1,000 feet inside the Harvey Locks on the Harvey Canal at Mile Marker 98. Conley Marine’s shipyard features a full machine shop, a 500T dry dock, and a bulkhead for topside work. Our qualified staff, well-versed in regulatory compliance will get your boat back to work quickly, with minimal downtime and expense.

A few things we’re great at

We know that a boat not in operation cannot make money.

Our goal is to get your boat underway quickly with quality service.

Maintenance and Repair

Conley has a long history with department of defense maintenance and repair from maintenance analysis and planning to mobile, worldwide repair. We know the importance of maintenance to safe and efficient operations. When a boat is down for repair, it cannot make money. Proper maintenance and planning will increase vessel availability and it’s ability to contribute to the bottom line.

Shipyard Services

We know that shipyard visits are costly, not only in the work being performed but the time off contract. By working together as a team, we can have your boat underway quicker and at a higher quality than our competitors.

The secret of success

Understanding our customers challenges and developing solutions to increase operational availability and reduce cost.

Maintenance & Repair

All of the maintenance management, maintenance planning and regulatory assistance means very little without quality maintenance and repair services. We combine all of these qualities in our M&R services to ensure the best quality and highest operational availability.

Maintenance Planning

Unscheduled maintenance is costly. Maintenance planning helps to schedule maintenance when it is convenient for you, not when the boat has a failure while under contract at an inconvenient time.

Maintenance Management

A maintenance plan is all well and good, but without quality management, the plan will inevitably fail. Conley Marine has many years of experience with Department of Defense and Maritime maintenance management and planning